Optitex – Introduction

#Optitex #Tutorial

04/03/2024

5 min

The Optitex program runs in a Windows environment, and is adapted to work with almost any peripheral equipment. In practice, this means that it can work with most input devices – digitizers, as well as with most printers or plotters. However, due to the specifics of the software – we recommend using plotters designed for the textile industry, with a wide working field and high printing speed.

The program consists of parts:

PDS – digitizing, construction and modeling, grading

MARK – typeface layouts, nesting and optimization

An extremely important feature of the system is its modular design. This means that each of the modules described below can be installed independently and at any time – so you can freely expand your system or change its configuration.

- creation of derived elements such as yokes, stitching, lining, etc.

- automatic creation of new elements by splitting or joining existing elements, preserving the applied parameters

- automatic addition of seam allowances when splitting elements and removal of these allowances when joining them

- working on symmetrical elements – all changes made on one side of an element are automatically transferred to its other side, preserving all the desired parameters

- adjustment of model elements to a particular fabric in terms of its report or shrinkage

- accurate measurements of the entire model, individual elements, selected line taking into account grading parameters and seam allowances in relation to linear lengths and geometric distances

- input of darts, pleats, pleats, buttons, internal elements with automatic consideration of grading values

- introduction of different types and types of notches with determination of its position in the basic size and the next graded size

- creation of libraries of templates, rules for grading an element or part of an element

- creation of element zone map, where any change introduced to a mapped element can be automatically introduced to individual elements

- copying fragments of seams from one element and pasting them into any fragment of the same or another element

- creating a seam allowance by marking the points of the seam sequentially and opening it while extending the element

- gluing a seam allowance while pulling the element apart

- cutting the arms of a seam along a predefined arc

DIGITALIZATION

Enter traditional templates into computer memory using a 16-button cursor. The size and shape of the elements do not matter, as both small elements and very large elements that do not fit on the board can be digitized.

Głównymi zaletami modułu są:

- smooth digitalization of curve lines

- constant preview of the inserted element

- possibility to enter all types of points, notches, internal lines, darts, buttons, etc.

- the possibility to enter elements in the grading grid while maintaining full sizing

- possibility to enter more elements without moving away from the digitizer, without immediately describing them and defining a straight thread or reference line

- ability to undo incorrect operations

- possibility to configure the digitizer panel according to the operator’s needs

- possibility to return to digitizer of already closed element and make correction

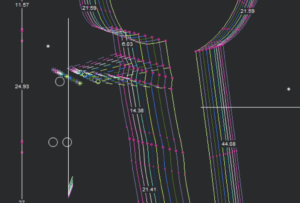

GRADING

Garment grading is simply defined as changing the size of the pattern. So it means that a new size of a particular garment is created. Optitex module allows grading of templates according to: girth, height and both variables using so-called grading variations. The grading process can be done in various ways:

- by entering the template increment value in the grading table at a given point.

- using previously prepared libraries of grading rules.

- using the mouse cursor, that is, manually moving the point to a certain position on the screen and automatically entering these values into the grading table.

TAILORING

PDS’s built-in Measuring Tailoring option allows you to quickly tailor a model to each customer’s unusual needs or for individual orders. The gauge table works closely with the item dimension table.

3D VISUALIZATIONS

An innovative solution that plays a key role in the process of designing and preparing templates for production. Through virtual fitting, it allows for quick verification of the correctness of the model, and thus for almost complete elimination of costs associated with trial sewing of prototypes. It allows direct contact between the design department and the pattern shop.

Using libraries of fabrics, seams and accessories (i.e. buttons, zippers, embroidery), the designer can quickly change the appearance of the model and the properties of the fabric used, change its color or choose a completely different type. By being able to change a number of avatar parameters, it allows to check the assortment on different types of silhouettes.

Another innovative solution is the option to generate files in formats that can be attached to offers developed in standard word processors (Microsoft Office Word, Excel, Star Office and others), posted on websites, or sent by e-mail. An extremely important point here is also the fact that there is no need to install Optitex software at the contractor’s site in order to read the uploaded files, which gives the possibility of quick verification of the model by the marketing department.