Refubrished Machines or Cheap Market Alternatives? How to Wisely Invest in Automated Cutting.

#Tutorial

21/01/2026

5 min

There is a bitter joke circulating in the manufacturing industry: “The most expensive machine in the cutting room is the one standing still and waiting for service.” Unfortunately, for many business owners, this joke becomes reality faster than they would like. Especially when the peak season is in full swing, client deadlines are unforgiving, and the “bargain machine” has just refused to work.

When discussing investments, we often hear the question: “Our budget doesn’t allow for a new line. Is it worth looking for a used machine?” The answer is: Yes. But only on the condition that you are buying technology, not a problem.

For many companies, this is the only way to start their adventure with automated cutting without gigantic upfront costs. However, the secondary market is a minefield. This article will guide you through the purchasing process so you know exactly what to demand from the seller.

Scenario 1: The “Bargain” from the Classifieds (The Risk)

This is the most common choice when the only criterion is the lowest purchase price. These machines usually find their way to the market from liquidated sewing factories in Western Europe or are imported in containers from Asia. On paper, the specs might look good. In practice, the client collides with reality:

-

Hidden wear and tear: You don’t know if the machine worked one shift cutting light apparel, or if it spent 5 years cutting heavy denim 24/7. The hour meter isn’t everything – material fatigue counts.

-

Outdated “Brain”: It often turns out the machine has old software that is incompatible with modern CAD systems.

-

Lack of support: When the machine stops, you are on your own. You have to import parts yourself, and local mechanics are often helpless.

The Result: The savings made at purchase vanish with the first invoice for electronics repair.

Scenario 2: The “Allcomp Certified” Program (Safety)

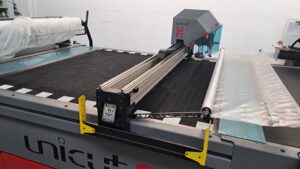

At Allcomp, we have adopted a model known from the automotive industry. We run a program where we buy back our own devices (Unicut/Prime models) from Clients who are upgrading their machinery park after years of use. Why does this change everything? Because we have known these machines since they were new. They were under our service care, so you are not buying blind.

What exactly do we do with the machine before it reaches you? We don’t just “dust off” the casing. The regeneration process at our factory in Katowice includes:

-

Full electronics audit: This is the heart of the machine. We check drivers, motors, and cabling, eliminating the risk of sudden failure.

-

Wear parts replacement: Consumable elements (table bristles, belts, bearings) are replaced with new ones or regenerated to factory parameters.

-

Software Update: This is crucial. We install the latest possible software for the given series so you can work according to current standards.

-

Warranty: We release the machine with a start-up warranty. We are confident in our work.

Being operational isn’t enough – ADAPTATION counts

This is the most important point that most buyers forget. A cutter is not a universal “out of the box” device. Every machine was once configured for a specific client.

Real-life example: The previous owner sewed delicate lingerie. The machine has a lower-power vacuum pump and a specific knife. You produce upholstered furniture and need to cut thick foam and hard fabrics.

Buying from an ad: The machine will be inaccurate, the material will shift, and blades will break. Buying from Allcomp: We will rebuild it for you. Before the machine leaves the hall, our engineers will adjust the vacuum power, the head, and cutting parameters specifically for your material. What’s more – we invite you for tests. You will see how the “used” machine cuts your material before you spend a single dime.

Who is this solution for?

Investing in a regenerated machine is a wise choice if:

-

You are transitioning from a manual cutting room to an automated one and want to safely test the technology.

-

You need a machine “right now” (availability in a few days).

-

You are looking for a proven “workhorse” that simply needs to earn money, without the need to invest in the newest gadgets.

Before you buy, ask the seller 3 questions

Regardless of where you decide to buy a used machine, ask the seller these questions. The answers will tell you everything about the risk:

-

“Who will come to service it if the machine stops next Tuesday?” (At Allcomp: our local service).

-

“Do you have spare parts on the shelf, or do they need to be imported?” (At Allcomp: we have our own warehouse and parts on the shelf).

-

“Can I come with my roll of material and test the machine?” (At Allcomp: always, or you can send us your material and we will test it for you).

If you are looking for a safe start in automation, contact us below. We will help you choose a machine that will truly strengthen your production, not become its bottleneck.