Which fabric cutter to choose in 2026? – Tutorial

#Tutorial

13/01/2026

4 min

“Which cutter will be better – single-layer or multi-layer?”

And almost always, the answer is the same:

It depends.

This is neither an evasion nor a marketing ploy. It is a technical fact.

In cutting technology, there is no universal solution because every cutting room operates under different conditions: with different materials, at a different production pace, and with different organizational constraints.

This article opens the “It Depends” series – a sequence of publications in which we answer the questions that most frequently arise during sales meetings and pre-implementation analyses. No oversimplifications, no slogans – just figures and practice.

Single-layer vs. Multi-layer – a difference that transforms the entire cutting room

Choosing a cutting technology is not a decision about the machine alone.

It is a decision about:

- cutting room throughput,

- the number of operators,

- operating costs,

- production flexibility in the coming years.

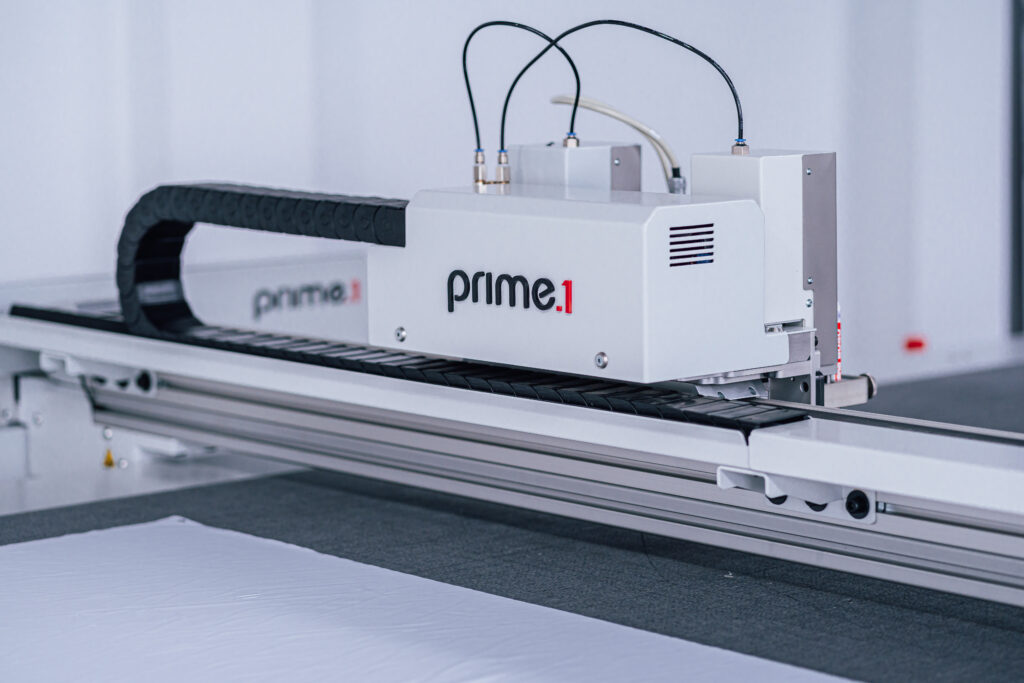

Single-layer cutter – speed and flexibility

Single-layer technology excels where variability and rapid response are key. Typical applications:

- short and medium series,

- made-to-order production,

- frequent changes of materials and patterns,

- materials with prints, repeats (reports), or grain direction,

- prototyping and R&D departments.

Technological features:

- cutting directly from the roll,

- no need for additional consumables (film and paper),

- high cutting speed.

Efficiency:

- approximately 400–600 linear meters (lm) per shift,

- however, actual efficiency depends on the number of pattern changes and the complexity of the elements.

A single-layer cutter often “earns its keep” not only through speed but through the lack of material waste and short production setup times.

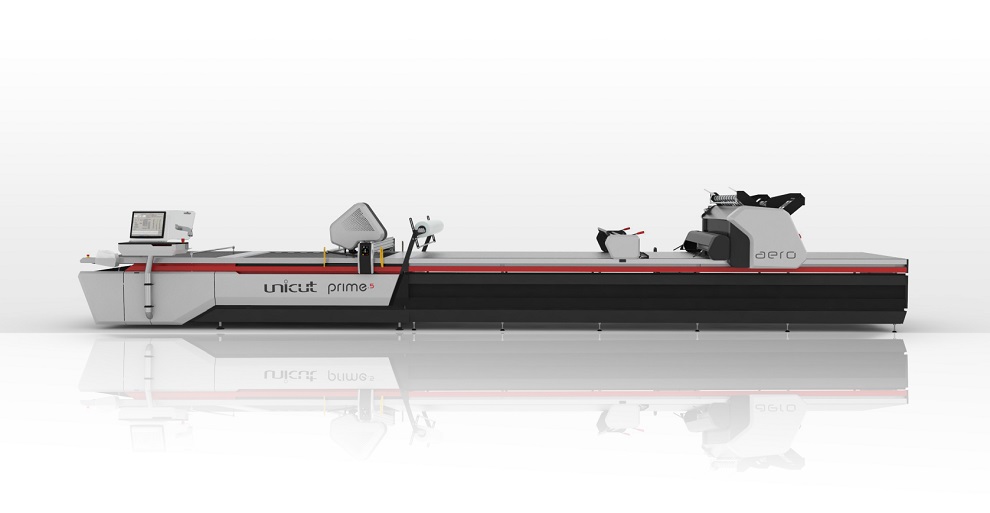

Multi-layer cutter – throughput and low unit cost

Multi-layer technology was designed for continuous and repetitive work. Typical applications:

- large production series,

- repetitive models,

- mass production (apparel, automotive, technical textiles, bedding),

- cutting high-loft materials like wadding/batting.

Technological features:

- cutting multiple layers in a single cycle,

- the necessity of spreading and using sealing film (sometimes additionally paper as the first layer),

- high process stability during long runs.

Efficiency:

- 1,000–1,500 linear meters (lm) per shift,

- and under the right conditions, even significantly more.

However, it should be noted that:

- film, paper, and ply preparation generate constant operating costs,

- with frequent model changes, the machine may operate below its potential.

What about “intermediate” solutions?

An increasingly common compromise includes:

- multi-layer cutters with limited ply height (e.g., 6–8 layers),

- hybrid configurations combining features of both technologies.

Such solutions:

- occupy a footprint similar to a single-layer machine,

- allow working with anywhere from 1 to several layers,

- offer efficiency of up to 2,000 lm/shift while maintaining flexibility.

In practice, they are chosen by companies that:

- currently produce short series,

- but plan for volume growth within the next 2–3 years.

Industry is not enough – the actual process is what matters

A frequent mistake when choosing technology is thinking in terms of the industry category. In reality, two companies from the same industry may need completely different solutions.

Example – upholstered furniture:

- Company A: a few models, large series – a multi-layer cutter operates optimally.

- Company B: custom/individual production, various fabrics – several single-layer cutters provide higher throughput for the entire department.

The primary material is not everything

In profitability analysis, the following are often overlooked:

- wadding/batting,

- felt,

- non-woven polypropylene (wigofil),

- foams,

- technical layers.

When summed up, it often turns out that:

- the total yardage to be cut justifies multi-layer technology,

- even if the primary material itself would not suggest such a choice.

Why does the answer always sound like “it depends”?

Because a correct decision requires answering several key questions:

- What are the actual daily and weekly volumes?

- How often does the model or material change?

- How many layers are we actually cutting (including accessories/interlining)?

- How much floor space is available in the hall?

- Is flexibility more important, or maximum throughput/efficiency?

Only a comparison of these data points allows for selecting the right technology, rather than just a machine.

Contact us, and we will help you select the right cutting technology for your needs.